Hub bearing unit is developed on the basis of standard angular contact ball bearings and tapered roller bearings. It combines the two sets of bearings as one. It has the advantages of good assembly performance, can omit clearance adjustment, light weight, compact structure, large load capacity, for sealing bearings can be loaded into grease beforehand, omit the external hub seal and avoid maintenance, etc., and has been widely used in cars. There is also a trend of gradually expanding the application in the truck.

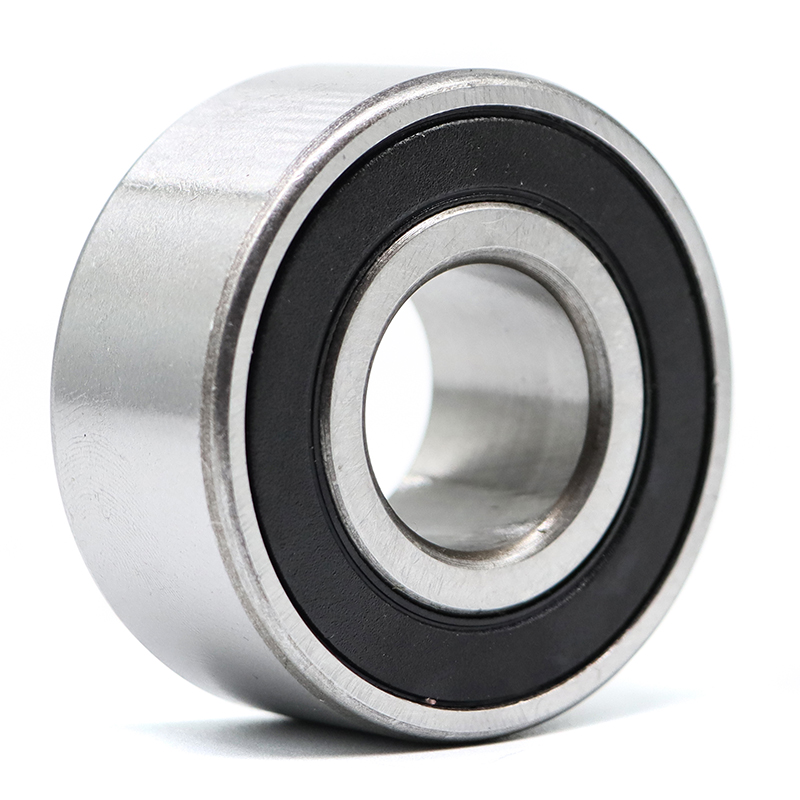

Hub bearing is the main role of bearing and provide accurate guidance for the rotation of the hub, it bears both axial load and radial load, is a very important part. The traditional automobile wheel bearings are composed of two sets of tapered roller bearings or ball bearings. The installation, oiling, sealing and clearance adjustment of bearings are all carried out on the automobile production line.

This structure makes it difficult to assemble in automobile production plants, high cost, poor reliability, and the car in the maintenance point maintenance, but also need to clean, oiling and adjustment bearings.

Main function: It is bearing and provide accurate guidance for the rotation of the hub, it bears both axial load and radial load, is a very important part.

Hub bearing is one of the key parts of the automobile, its main role is to carry weight and provide accurate guidance for the rotation of the hub, which requires it to bear not only axial load but also radial load.

Wheel bearings are important components of a vehicle’s braking, steering, and suspension systems. The one-piece hub assembly, located between the drive axle and the brake disc or drums, incorporates the hub, wheel bearings, ABS wheel speed sensor, and mounting flange.